Facts about the project

PhD Project: Dr. M. Zain-Ul-Abedin +++ Duration: 01.07.2017 – 30.06.2020 +++ Project funding: Bundesministerium für Bildung und Forschung (BMBF), Projektträger Jülich

The project is investigating whether underground gas storage (UGS) can be used to balance short-term fluctuations in energy demand in addition to seasonal use. It is part of the larger SUBI research project funded by the BMBF, which also includes borehole-scale studies and the analysis of salt caverns for UGS. The focus of the work at TU Darmstadt is on thermal-hydraulic-mechanical (THM) coupled multiphase models of porous reservoirs to evaluate the effects of high-frequency injection-production cycles on fault reactivation and caprock integrity. Among other things, this allows to determine the maximum safe injection pressure and, thus, the storage capacity of a UGS.

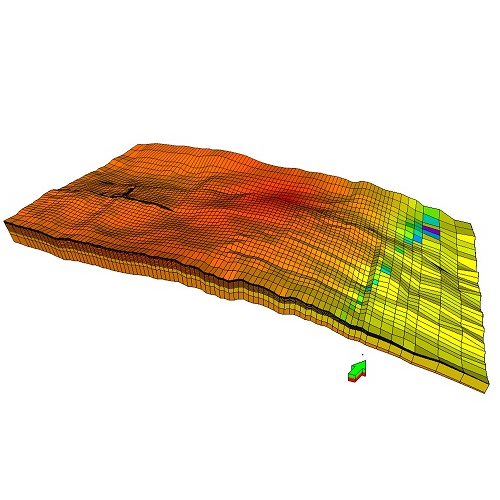

In addition to generic studies, the work focuses on a former natural gas field in the Molasse Basin east of Munich, for which a hypothetical conversion to an UGS is simulated. The workflow combines thermohydraulic (TH) calculations, based on Eclipse software, with mechanical (M) simulations using Techlog and Visage software. The geometry of the reservoir was created using seismic data and boreholes. The subsurface model shows a structure bounded by faults with an extension of 4 km in N-S and 8 km in W-E direction, respectively. The Eclipse simulation was calibrated using pore pressures which were measured at the start as well as during the gas production and subsequent shut-in phase. Mechanical properties (Young's modulus, Poisson's ratio, Biot coefficient, density), pore pressures, and an initial estimate of vertical and horizontal stresses are derived from well data using Techlog. This information is then used to parameterize a 3D geomechanical model in Visage (Petrel Reservoir Geomechanics). This model is coupled to a 3D Eclipse simulation through the interdependence of pore pressure, effective stresses, volumetric strain, porosity, and permeability. This combination of reservoir engineering and reservoir geomechanics provides valuable insight into the safe use of UGS, including injection-production cycles with high frequency (days to weeks).

- Zain-Ul-Abedin, M. & Henk, A. (2020): Building 1D and 3D Mechanical Earth Models for Underground Gas Storage—A Case Study from the Molasse Basin, Southern Germany. – Energies 2020, 13, 5722; doi:10.3390/en13215722.

- Zain ul Abedin, M., Henk, A., Rudolph, T., 2019. Coupling of flow and geomechanical simulations for short-term underground gas storage – a case study from the Bavarian Molasse Basin, DGMK/ÖGEW-Früjahrstagung, 25-26 April 2019, Celle, Germany.