Facts about the project

PhD project: Sonu Roy +++ Duration: 01.10.2022 bis 31.12.2025 +++ Project funding: Bundesministerium für Wirtschaft und Klimaschutz (BMWK) Projektträger Jülich (PTJ)

Status Quo & Outlook

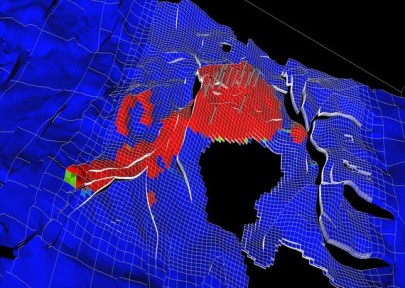

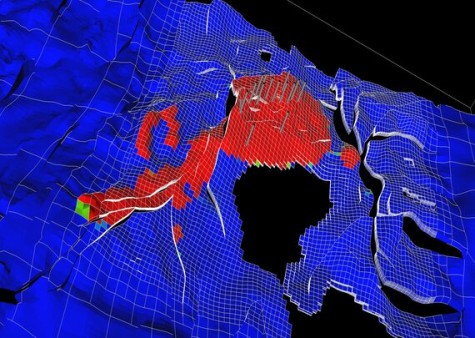

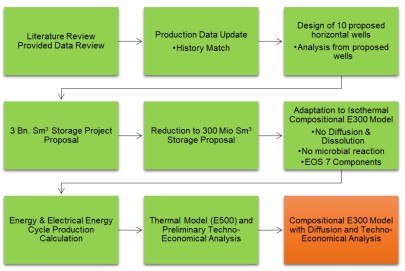

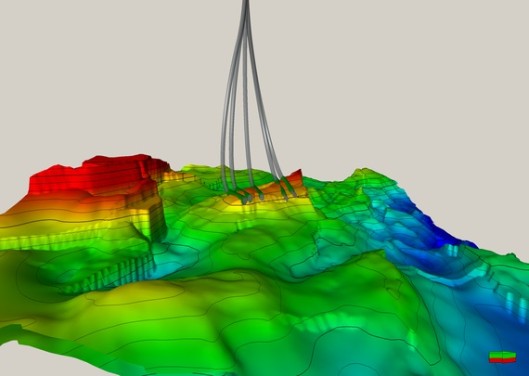

So far, dynamic models have been created for the two case studies and calibrated using production data. Based on this, various storage scenarios for hydrogen with different cushion gases have been simulated.

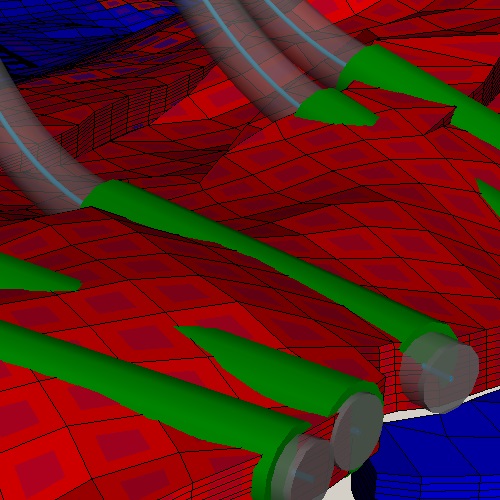

The next steps involve developing a Two-way coupling Geomechanical Model with Visage and Eclipse.