Geomaterial Science

Ongoing Projects

Functionally Graded Ultra-High Temperature Ceramics

Project Leaders

- Kerstin Stricker and Hans-Joachim Kleebe

Description

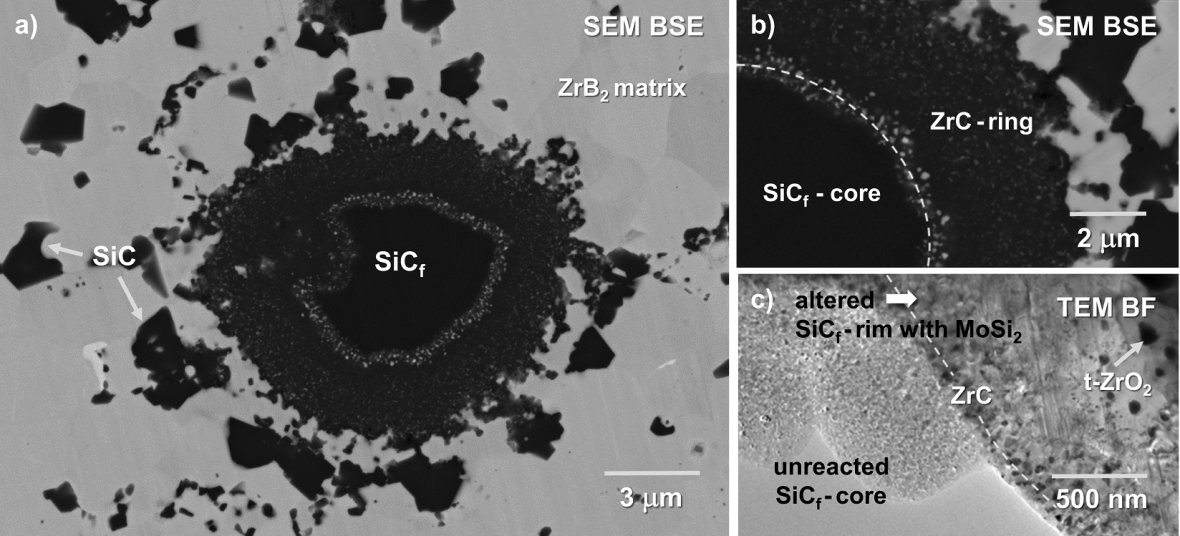

An innovative ZrB2-based SiC-fiber reinforced Ultra-High Temperature Ceramic (UHTC), with MoSi2 and ZrSi2 as sintering additives, emerged as a promising material able to withstand the exceeding harsh conditions in aerospace applications, in particular, of reentry-vehicles.

However, the major drawback in utilizing SiC-fiber reinforced ZrB2-MoSi2 materials is the degradation of the SiC fibers due to permeation of MoSi2 into the loose fiber structure during sintering. With the help of a ZrB2-Si3N4 or ZrB2-PDCs (polymer-derived ceramics) buffer layer, a degradation of the SiC-fibers can be inhibited. Moreover, even under high-temperature oxidative conditions, this buffer layer proofs to be an effective diffusion barrier for MoSi2.

Electron microscopy investigations (SEM and TEM) are employed to understand the influence of the buffer layers on the diffusion behavior of MoSi2 in detail, which in turn enables us to further optimize this promising material system.